(Summary description)

(Summary description)

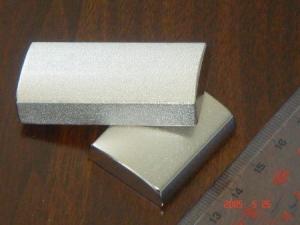

Nd-Fe-B can be divided into sintered Nd-Fe-B and bonded Nd-Fe-B. bonded Nd-Fe-B has magnetism in all directions and is corrosion-resistant; The sintered Nd-Fe-B is easy to corrode, so the surface needs coating, generally including zinc plating, nickel, environmental protection zinc, environmental protection nickel, nickel copper nickel, environmental protection nickel copper nickel, etc. The sintered NdFeB is generally divided into axial magnetization and radial magnetization, which is determined according to the required working face.

NdFeB surface treatment:

With the thawing of the patented technology of sintered NdFeB in Japan, Germany and the European Union and the concerted efforts of major sintering manufacturers in China, the grade of sintered NdFeB products has been greatly improved With the continuous improvement of its comprehensive performance in the field of high-tech application, the requirements for sintered Nd-Fe-B surface treatment are also greatly improved. The traditional treatment methods can not meet the requirements of the progress of the industrial chain Scientific research institutions such as University of Electronic Science and technology, Sichuan University, Jiaotong University and Ruishi rice have essentially improved the principle of surface treatment and the development of industrial application process from the perspective of micro molecular structure. After four years of efforts, they have made breakthroughs in key technologies Nano (3010) chelate film is treated without coating. This technology is an original technology. The active groups contained in the nano film have strong resistance to moisture, oxygen, chloride ion (CL), carbon dioxide (CO2), etc Corrosion resistance and adhesion of organic resin are greatly improved Its excellent surface physicochemical properties will have a significant impact on the application field

In December 2013, the treatment process was systematically tested by Sichuan University and Chinese Academy of Sciences Its corrosion resistance can be used for 20-30 years in marine climate conditions, and can be widely used in sea based wind power generation The surface adhesion force is more than 20MPa, which can be widely used in permanent magnet high-speed motor, special motor, electric vehicle motor, UHV, high-voltage DC power supply system, fast charging system, Aerospace Military Industry and other fields.

Common surface treatment methods:

1. Non plating treatment of nano (royce3010) Chelating film; (3010 means that the film layer contains more than 3 active chelating groups, and the thickness of the film layer is 10 nm);

2. Phosphating;

3. Electroplating;

4. Electrophoresis;

5. Vacuum vapor deposition;

6. Electroless plating;

7. Organic plastic spraying;

Scan the QR code to read on your phone

About us Recruitment Environment

News Marketing network Download

Product Application Product Center Contact Us

Contact us:

Telephone: 0472-5217177

Fax: 0472-5217478

Website: www.cnkrwc.com

Address: high-tech industrial base, rare earth high-tech industrial development zone, baotou city, Inner Mongolia

Mobile QR code